Cold-Drawn Wire and Custom Wireformed Products

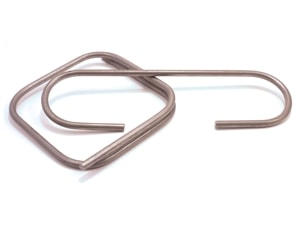

With our complete wire forming and fabrication capabilities, Alabama Wire, Inc. manufactures custom masonry tie bars in various lengths and diameters for the construction industry. For one particular customer, we fabricate the tie bars highlighted here from #2 smooth reinforcing steel. These tie bars are designed specifically for use in concrete block (CMU) masonry walls, which are common in institutional and commercial construction.

Our large production facility houses programmable equipment that enables us to manufacture these reinforcing tie bars with a high degree of consistency and repeatability. Production involves wire straightening, cutting the wire to specified lengths, and then creating the 2D shape on our specialized wire bending machinery. We engineer our production streams to promote cost-efficiency at specified lot sizes to provide the best value to the customer on each individual order.

Constructed from .250" diameter bright basic steel wire, we manufacture these tie bars in various 2D configurations as needed by the client. We mark job-specific information directly on the parts to indicate the correct end-use placement, which promotes efficiency at the construction site. Manufactured to within ±0.003" tolerances on diameter and ±0.062" on length, the cold drawn, cold finished steel wire tie bars are compliant with ASTM A510, ASTM A853, and Concrete Reinforcing Steel Institute standards.

With 2D wire forming as one of our core strengths, the stability of our manufacturing process enables us to deliver products that consistently meet the customer specifications. As a trustworthy supplier to this customer for many years, we provide predictable lead times and have an exemplary record for on-time delivery. We also supply custom rebar products to many other customers throughout the Southeastern United States.

To learn more about these custom products or the processes we use to manufacture them, contact us today.

Alabama Wire, LLC

3000 Highway 11, Pelham, AL 35124

Toll Free: 1.800.749.3504

Phone: 205.663.6743

Fax: 205.664.9156

Email: [email protected]