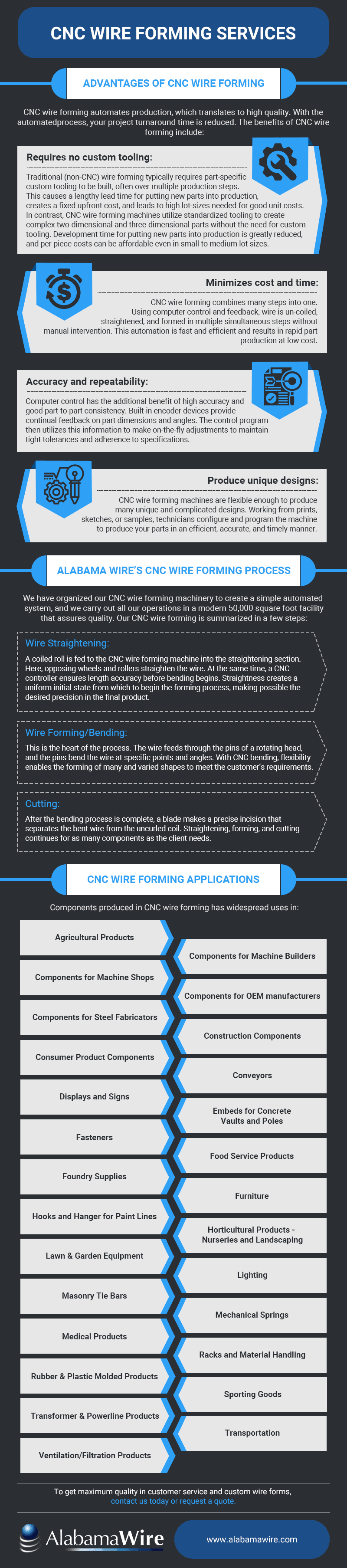

Advantages of CNC Wire Forming

CNC wire forming automates production, which translates to high quality. With the automatedprocess, your project turnaround time is reduced. The benefits of CNC wire forming include:

- Requires no custom tooling: Traditional (non-CNC) wire forming typically requires part-specific custom tooling to be built, often over multiple production steps. This causes a lengthy lead time for putting new parts into production, creates a fixed upfront cost, and leads to high lot-sizes needed for good unit costs. In contrast, CNC wire forming machines utilize standardized tooling to create complex two-dimensional and three-dimensional parts without the need for custom tooling. Development time for putting new parts into production is greatly reduced, and per-piece costs can be affordable even in small to medium lot sizes.

- Minimizes cost and time: CNC wire forming combines many steps into one. Using computer control and feedback, wire is un-coiled, straightened, and formed in multiple simultaneous steps without manual intervention. This automation is fast and efficient and results in rapid part production at low cost.

- Accuracy and repeatability: Computer control has the additional benefit of high accuracy and good part-to-part consistency. Built-in encoder devices provide continual feedback on part dimensions and angles. The control program then utilizes this information to make on-the-fly adjustments to maintain tight tolerances and adherence to specifications.

- Produce unique designs: CNC wire forming machines are flexible enough to produce many unique and complicated designs. Working from prints, sketches, or samples, technicians configure and program the machine to produce your parts in an efficient, accurate, and timely manner.

Alabama Wire’s CNC Wire Forming Process

We have organized our CNC wire forming machinery to create a simple automated system, and we carry out all our operations in a modern 50,000 square foot facility that assures quality. Our CNC wire forming is summarized in a few steps:

- Wire Straightening: A coiled roll is fed to the CNC wire forming machine into the straightening section. Here, opposing wheels and rollers straighten the wire. At the same time, a CNC controller ensures length accuracy before bending begins. Straightness creates a uniform initial state from which to begin the forming process, making possible the desired precision in the final product.

- Wire Forming/Bending: This is the heart of the process. The wire feeds through the pins of a rotating head, and the pins bend the wire at specific points and angles. With CNC bending, flexibility enables the forming of many and varied shapes to meet the customer’s requirements.

- Cutting: After the bending process is complete, a blade makes a precise incision that separates the bent wire from the uncurled coil. Straightening, forming, and cutting continues for as many components as the client needs.

Alabama Wire not only guarantees quality in the process but also in the material of our components. Our quality control procedures include:

- Reviewing orders

- Ordering material from qualified suppliers

- Inspecting upon receipt

- Using computerized identification and tagging systems

Finishes

Our wire spools are shaped and finished as:

- Pre-Galvanized Zinc Finish

- Clear Zinc Electroplate

- Yellow Zinc Electroplate

- Black Zinc Electroplate

- Olive Drab Zinc Electroplate

- Powder Coating

Secondary Operations Available

Other than custom wire forming, we also provide:

- Secondary bending operations

- Chamfering

- Deburring

- Drilling

- Swaging or flattening

Materials Used in the Wire Forming Process

Among the list of materials used in CNC wire forming are:

- Low Carbon Steel

- Medium to High Carbon Spring Stee

- Stainless Steel

- Aluminum

CNC Wire Forming Applications

Components produced in CNC wire forming has widespread uses in:

- Agricultural Products

- Components for Machine Builders

- Components for Machine Shops

- Components for OEM manufacturers

- Components for Steel Fabricators

- Construction Components

- Consumer Product Components

- Conveyors

- Displays and Signs

- Embeds for Concrete Vaults and Poles

- Fasteners

- Food Service Products

- Foundry Supplies

- Furniture

- Hooks and Hanger for Paint Lines

- Horticultural Products - Nurseries and Landscaping

- Lawn & Garden Equipment

- Lighting

- Masonry Tie Bars

- Mechanical Springs

- Medical Products

- Racks and Material Handling

- Rubber & Plastic Molded Products

- Sporting Goods

- Transformer & Powerline Products

- Transportation

- Ventilation/Filtration Products

Introduce Wire Forming Quality Into Your Product

Alabama Wire is committed to delivering formed and fabricated wires in a short time and at a low cost. With more than 30 years of experience, our technicians support component production from design to prototyping to the final product. To get maximum quality in customer service and custom wire forms, contact us today or request a quote.